Troubleshooting common PVC extrusion issues like burn, gel, and die lines is crucial for maintaining product quality and production efficiency. These defects are symptoms of process imbalances and can be resolved by systematically checking key parameters.

Burn Marks

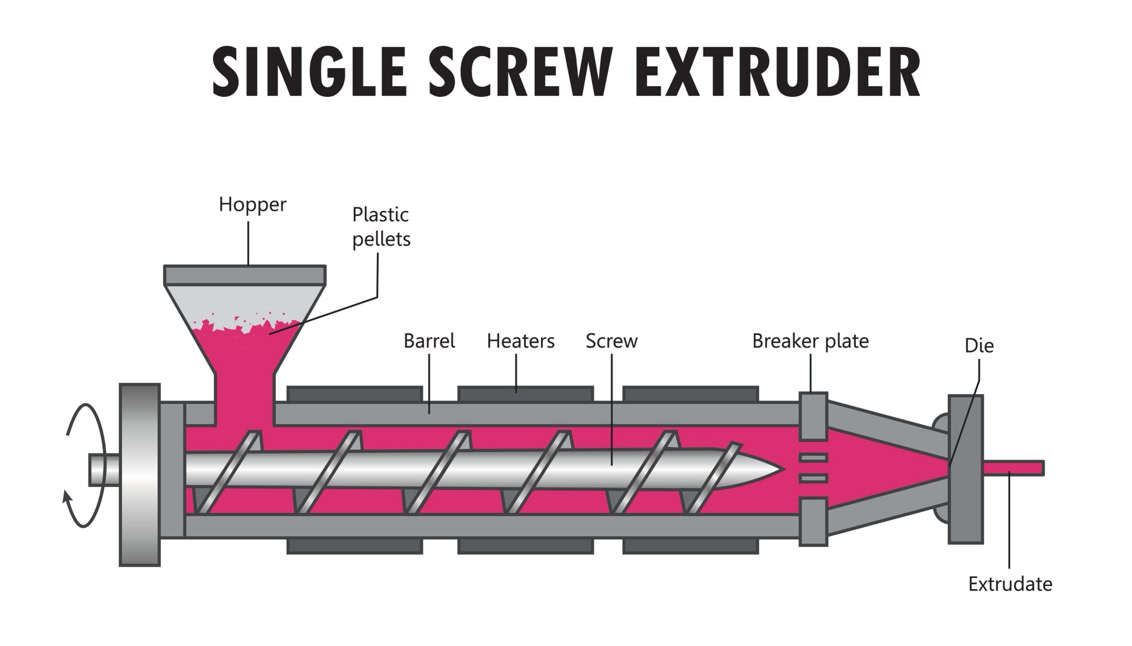

Cause: Burn marks appear as black or brown specks and are caused by localized overheating and degradation of the PVC compound. This can happen when material gets trapped and overheated in stagnant zones within the extruder or die.

Solution:

- Check Temperature Profile: Ensure the temperature profile is set correctly and the heaters are functioning properly. A lower temperature in the last zone or die can sometimes cause a bottleneck that leads to localized overheating.

- Inspect Die and Screw: Clean the die and screw regularly. Remove any buildup of degraded material, as this is a primary source of contamination that leads to burn marks.

- Adjust Screw Speed: Running the screw too fast can create excessive friction, increasing melt temperature beyond the PVC's thermal stability limit. Reduce the screw speed to lower shear heat.

Gel (Fisheyes)

Cause: Gels, or "fisheyes," are small, clear, unmelted particles that show up in the final product. They are typically caused by incomplete fusion of the PVC compound.

Solution:

- Increase Temperature: Raise the barrel and die temperatures in small increments to ensure the compound reaches its proper processing temperature.

- Adjust Screw Design & Speed: Ensure the screw design is appropriate for PVC, providing sufficient shear to melt the compound. A slightly higher screw speed can increase shear and improve fusion, but be cautious not to cause burn marks.

- Preheat the Material: Ensure the material is stored and handled properly. Moisture or cold material can inhibit proper melting.

Die Lines

Cause: Die lines are fine, longitudinal streaks or scratches on the extruded product. They are usually caused by an obstruction or imperfection on the surface of the die.

Solution:

- Clean the Die: The most common cause is a small piece of foreign matter or hardened PVC stuck in the die orifice. Disassemble and thoroughly clean the die using brass tools or specialized cleaning compounds to avoid scratching the die surface.

- Inspect the Die Surface: Look for physical damage, such as scratches or nicks, on the die lip. If the die is damaged, it may need to be polished or replaced.

- Check Material Contamination: Ensure the compound itself is clean and free of foreign particles that could scratch the die as they pass through.

By carefully monitoring these parameters and performing routine maintenance, you can significantly reduce these common extrusion problems and ensure a consistent, high-quality output.